LED and colour

Singapore, 9th September 2013

A bit of tech talk today…not too much, but a bit as the LED colour issues really confuses people out in the field. In one of our Hotel projects we have some colour issues on site which are really difficult to explain to the client. The main frustrating issue for us as lighting designers is the fact that we have specified the performance parameters as good as possible at the time (specs date from over a year back). Meanwhile some water has gone under the bridge and lights have been installed on site. Some as per our original specification, but some being “equivalents” from trusted/ reputable manufacturers. Our specification at the time specified the colour temperature and colour rendering, but not any specific requirement in regards to binning…

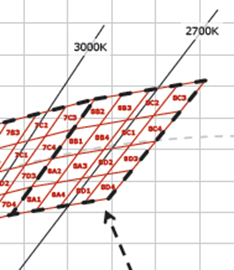

Now we find ourselves with LED light sources on site that presumably all have the same colour qualities (Tk and Ra) but all have a clearly different colour appearance! How to explain to the client. A few things have happened…First of all not all light sources are from the same brand; this in itself now is cause for differentiation as it appears not all manufacturers follow the same binning strategy! Secondly not all manufacturers follow the same binning stringency. High end quality LED’s will be within the 4 McAdams, while the “general” quality is way higher up. On top of that they can be binned in say the red blue or green quadrant. This of course gives way to enormous colour inconsistency. Last but not least there is the interaction of the LED colour (we are talking “2700K” here) with the various interior material finishes. Add these variables together and you have the disaster we are now facing with colours all over the place. While we can not really control the material finishes we can control too a great extend the colour of the LED. The lesson learned really is to a) make sure you minimise the number of LED brands (certainly in a same space) and b) make sure you specify the highest possible (reasonable) binning batch (<4 McAdams) preferably by even indicating from which quadrant you want them from. Seems quite tedious but in applications where colours are critical I think we will need to do that…

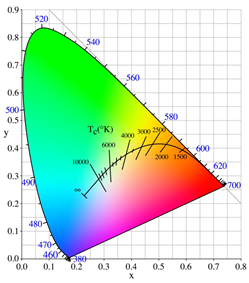

Light Watch 4-151: Here is the colour triangle showing where the colour temperature black body lines are and a typical binning quadrant which relates to 2700K…

The long awaited book compilation of Martin's first year of blogging is available. Order now.

The long awaited book compilation of Martin's first year of blogging is available. Order now. Feedspot Top 100 Lighting Blogs

Feedspot Top 100 Lighting Blogs