The week that was 24 – 28th July 2017

Singapore, weekend 29-30th July 2017

As I am contemplating the contribution of other collaborators to the blog, it’s time I do one myself again…J. It has been very inspiring and rewarding for me to see the contributions of my staff to this blog. While I am the key man on which this practice is built there is no way I could do all of it by myself. The contributions of each and every member of my team, small or big, in Singapore or abroad make KLD to what it is today. The team’s dedication, their passion and the commitment to do a good job, learn, grow and get better all the time has been heartwarming! I am truly blessed with such a dedicated team and collaborators!

This weekend I am back in Singapore after a heavy week of travelling. As I move on in years the travelling part is the part that seems to get to me most. I know how to deal with difficult clients, collaborate with designers and project managers who have an attitude, work my way through site issues and contractor fits, but keeping up travelling fitness requires pace, rest and discipline. This week I had a project meeting on a shipyard more than 250 km (!) south-west of Shenzhen to meet with team on site and check out the progress of a big luxury yacht we are working on. My team had been to site before and I was forewarned by them that the trip could be arduous…little did I realise at the start of my 3 day journey this week that I would spent about 10 hours in a plane (delays) and 20 hours travelling by car (traffic jams) for just over 4 hours total in meetings. The ship building facility is an hour out of Zuhai so arguably taking the ferry from Hong Kong to Zuhai and then on by car could be one way of reaching. However with both the client and the interior designer holding office in Shenzhen travelling through Shenzhen was decided. We did fly in via Hong Kong though because of the larger choice and flexibility of flights in from and out to Singapore. It was just unfortunate that the subsequent road trip the next day from Shenzhen took more than 5 hours due to unexplainable traffic jams…at one point we were literally stuck for over an hour on the highway not moving an inch…always be prepared for the unexpected! Add to that the searing heat of 35 degree plus and you can imagine the situation…

Anyhow in the end it was an important meeting, both on site at the shipyard as well as in Shenzhen with the designers. As with all projects coordination and cooperation are critical for a good end result and in China probably more than elsewhere, the decorum of the “boss” being present in high profile projects, regardless the costs, is seen as a sign off importance and prestige given to the project. While no major decision were taken that could not have been made without me present, making the effort to go to site to check and review the progress of the yacht building, discussing lighting issues with the site team was seen as a great sign of respect and show of our commitment to bring this project to a successful completion. We still have a year or so to go till the official launch and baptism of the ship, but the super structure starts looking good and I can’t wait for the start of the interior fit out…

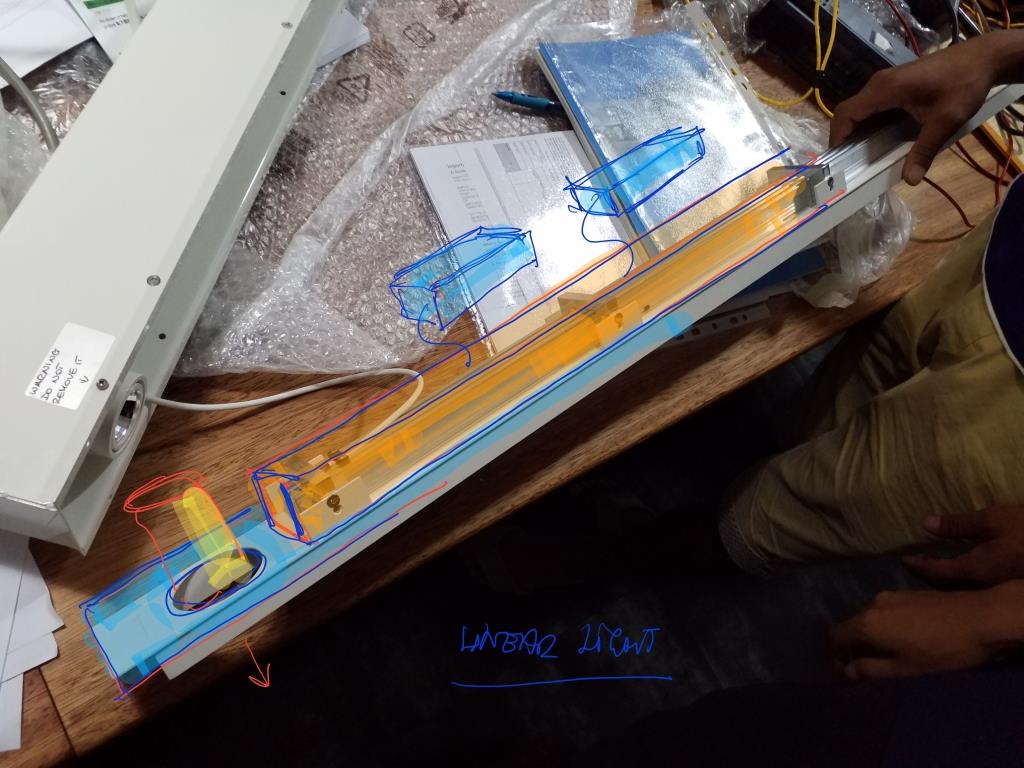

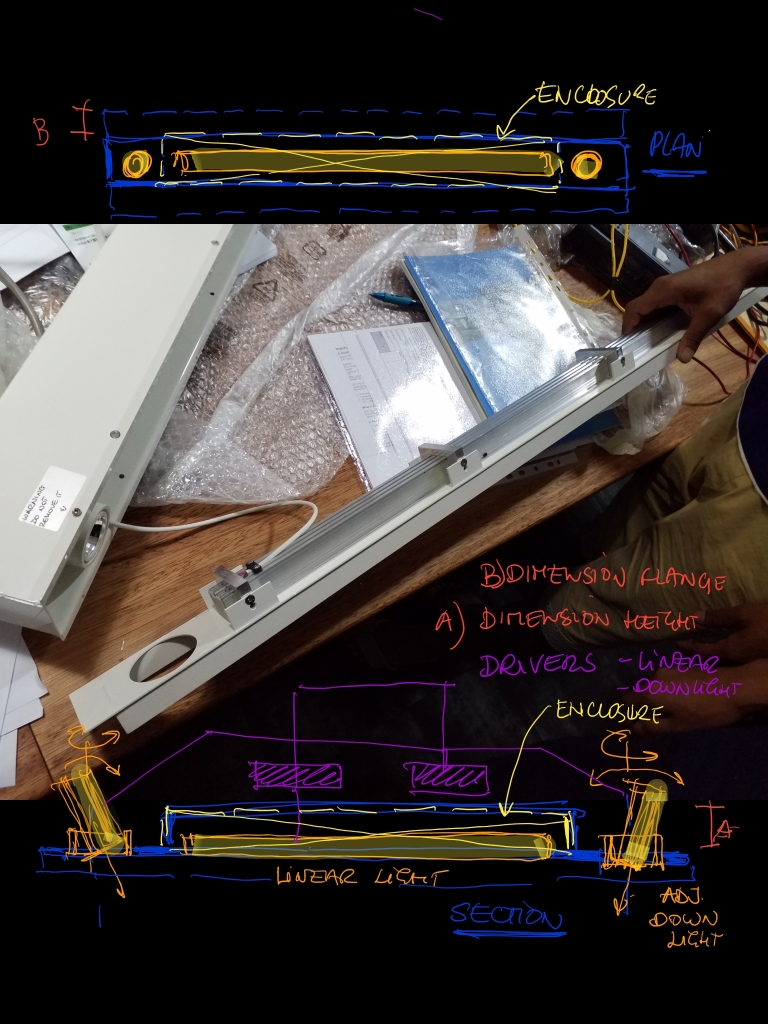

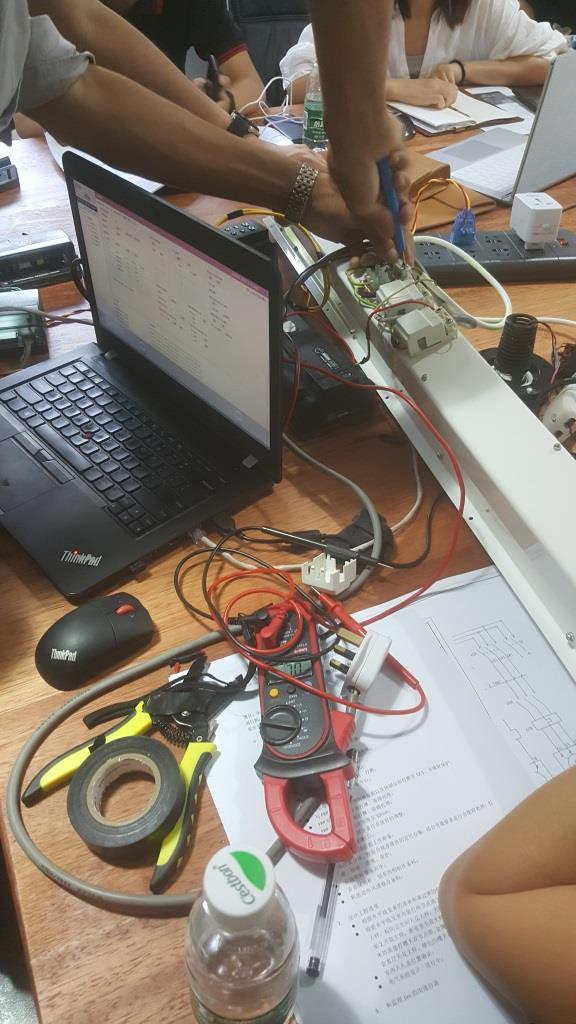

For this project we have designed a custom integrated linear fitting of which we had brought a sample for testing and assessment by the installation team. The aim of the sample was to establish a few things:

1- are the dimensions workable

2- are the lighting effects smoothly dimmable (the dimmer specialist had come from Shenzhen to test)

3- how best to fix it in the ceiling

4- check the lighting performance in the actual space

5- get any other feedback from interior design and site team

We got all the answers needed and priced ourselves happy that we had insisted on this meeting as several issues in regards to dimensions, weight, installation and dimming were discussed, adapted and revised to suit the site conditions and dimmer capabilities. As often the case there is less ceiling space in some areas as previously assumed prompting us to redesign the recessed part of the fitting accordingly. No major problems expected but nipping this issue in the bud at this stage is crucial. Material finishes, optics and dimming protocols (DMX and DALI) will be reviewed to provide the client with an upfront budget estimate prior to proceeding.

The return to Shenzhen was a bit less strenuous but still a long journey and not surprisingly on arrival back at the hotel I went straight to bed after having had a shower to drench off the tiring and sweaty day we had experienced…The next morning we had a short follow up meeting with the interior designer to discuss the yacht issues from the day before as well as reviewing some updates on another mixed development project we are working on with them…but that is for another time…

Have a great weekend 🙂

The long awaited book compilation of Martin's first year of blogging is available. Order now.

The long awaited book compilation of Martin's first year of blogging is available. Order now. Feedspot Top 100 Lighting Blogs

Feedspot Top 100 Lighting Blogs