I feel the temperature rising

Singapore 26th September 2011

Back to LED again…the last few weeks I have been investigating LED (specifically the retrofit types, not so much the light engines) in depth to understand the limitations they have and the characteristics we need to look out for to achieve a successful installation. Today was another such day incorporating discussions with yet another lamp manufacturer. Note I say lamp (=light source) manufacturer, not fitting manufacturer, people who manufacture all core system components including lamp and all other essential elements such as driver and controls. Manufacturers have a tendency to put forward all the positive features of their lamps (conveniently) leaving out the potential negative site effects.

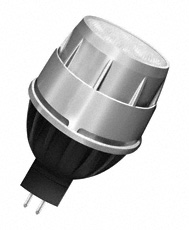

Today’s discussions centred mostly around the heat issues faced with LED’s, specifically after we discovered the problems with the Philips 10W Master LED recently. Now here is the deal…LED’s most critical point is the heat dissipated at junction point between LED and the circuit plate it is mounted on. Apparently it can get pretty hot up there (around 120 degr C I am told). The better the cooling the better the lamp works, so hence all these funky and ingenious heatsink designs we see apearing by various manufacturers. Philips went to the extent to built in a mini mechanical fan inside (!) the lamp to allow the lamp to be as compact as possible. A mechanical component in an electronic system? Seems like asking for trouble! What worries me most is that a 10 degr temperature increase can apparently cause a decrease in life of up to 50%! Really? So how do we control the heat dissipation in there? In the tropics it is hot and humid but at least the ambient temperature is reasonably constant. But Down Under we have day-night time temperature differences of more then 20 degrees on a day! Imagine the heat build up under tin-shed roofs…how is that going to work (or being controlled?). How do we define the acceptable light fittings for LED retrofit, as obviously enclosed types do not seem to be suitable.

The other issue relates to the compatibility between transformer and LED lamp. The transformer has wave curves, while LED has block shaped wave profiles. That obvioulsy does not match very well. No wonder there are so many non compatible transformers (!)…another subject for another day 🙂

In Light Watch today some pics of key players; Philips and Osram. I have added another (new kid on the block) player; Ecogreen which is a company that boosts ex-Philips and Osram engineers. Interesting to see how the products take shape…

Light Watch 170: MR16 retrofits

The long awaited book compilation of Martin's first year of blogging is available. Order now.

The long awaited book compilation of Martin's first year of blogging is available. Order now. Feedspot Top 100 Lighting Blogs

Feedspot Top 100 Lighting Blogs

Comments (3)